| Picture of the month | Historical overlook | Stone types | Picture gallery | ||

| Videos | Links | Downloadables | News, Offers | ||

| Contact | Administration | Anker Software | |||

| Visitors this month:10366 | |||||

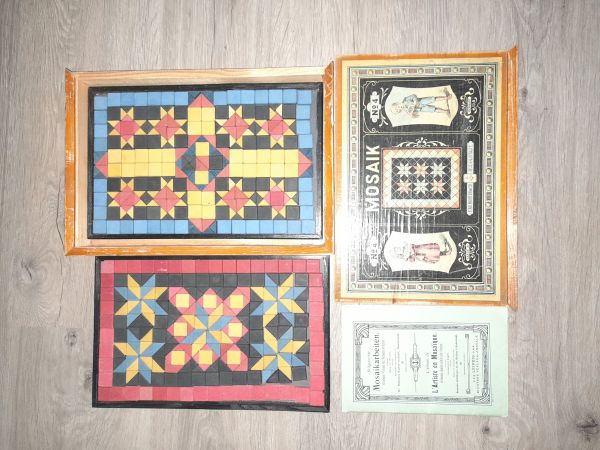

| Picture of the month2025 8 MosaicThis month I present three versions of mosaic sets. The first two are historical, and the third is made by the new factory. It is interesting to note how much the colour of the stones in the first box differs from the usual yellow / red / blue colours. This allows for the creation of very vivid and spectacular floors.  The stones in the second box match the usual colours of other sets, with only the black stones being distinctive.  The new factory set has the same colour scheme as the current era sets.  |   |